Guidelines for the assessment of geotechnical risks in open pit mines

Executive summary

This guidance material is concerned with the assessment of geotechnical risks associated with the development, operation and rehabilitation of an open pit mine within Victoria. Large mines which are considered to have significant ground stability risks to public safety, the environment, land, property or surrounding infrastructure may be declared by the Minister under the Mineral Resources (Sustainable Development) Act 1990 (MRSDA).

Declared mines are required to regularly submit reviews of stability assessments to the Department of Jobs, Precincts and Regions (the department) Earth Resources Regulation unit. The ongoing review of the Ground Control Management Plan (GCMP) is critical to the management of geotechnical risks on these large and complex sites. Declared mine stability requirements and processes are provided in Part 2 of Schedule 15 in the Mineral Resources (Sustainable Development) (Mineral Industries) Regulations 2019.

The assessment of geotechnical risks to public safety, infrastructure, the environment, land and property is required by the department's Earth Resources Regulation unit as part of the submission of a work plan for a new open pit mine or for a variation to a work plan for an existing mine. Work plans are required for all open pit mines where the areal extent of the excavation exceeds five hectares or five metres depth or where working practices including ground controls or wet working are necessary or where environmental assets are affected. The requirements for submission of a work plan or work plan variation are detailed in the Mineral Resources (Sustainable Development) (Mineral Industries) Regulations 2019.

Administration of Occupational Health & Safety (OHS) in mines (including safety issues associated with operating slopes within open pit mines), is carried out by WorkSafe Victoria (WorkSafe). This guidance material does not address geotechnical risks that are associated with the OHS issues of a site. All of these risks are considered separately by WorkSafe. This guidance material also does not address geotechnical risks associated with underground mining methods or quarries. For geotechnical considerations for quarries, refer to the Geotechnical guideline for terminal and rehabilitated slopes - Extractive industry projects (PDF 510.0 KB).

Under the National Mines Safety Framework (NMSF), a code of practice for both underground and open pit mines is currently under preparation. This guidance material is consistent with these codes and if there is an overlap, then this will be managed through the Memorandum of Understanding (MoU) between the department's Earth Resources Regulation unit and WorkSafe.

Geotechnical risks at a mine are defined as those risks associated with ground movements. Ground movements are typically limited to the area of the mine and to a region around the mine. Ground movements may be significant (such as subsidence or natural rebound) or catastrophic (such as batter collapse). Irrespective of the type of ground movements, it is possible for persons, infrastructure or the environment to be harmed. It is essential that the risks of harm arising from ground movements are minimised during the period of operation of the site, rehabilitation and post-closure.

A simplified method of assessment of the area potentially affected by mining induced ground movements and the geotechnical risks to public safety, infrastructure, land, property and the environment is presented. Guidance on the delineation of the area within which ground movements may occur is given. Identification of assets within the area of movement that could be at risk is required.

For each asset, the hazards arising from any ground movements and the level of risk to the asset for the given hazards should be elaborated. Where risks are deemed to be significant, the requirements for reducing the risks to a level that is as low as reasonably practical are recommended. The requirements for documenting the geotechnical risk assessment method and their inclusion in a work plan are summarised.

The steps in the assessment method are briefly:

- Definition of the Geotechnical Risk Zone (GRZ) within which the impacts on public safety, the environment, land, property and infrastructure should be examined.

- Identification of all current and planned assets (public access, infrastructure, land, property and environments) within the GRZ.

- Determination of any impacts from the GRZ applicable to each asset.

- For significant impacts an outline of all controls proposed to reduce the risk to as low a level as reasonably practical.

- For all significant impacts posing significant risks a statement may be required detailing the method to be used to monitor and evaluate ground movements and their impact on the asset during operation and rehabilitation of the site.

If geotechnical investigations are required to demonstrate that risk levels are as low as reasonably practical then these may be carried out by a competent individual or organisation and be undertaken in accordance with current best practice. Where the assessed risks are to be mitigated/managed through engineering and/or administrative controls then appropriate monitoring and evaluation may be adopted to demonstrate the ongoing safety of the site. When geotechnical investigations are not required, it is recommended that movement monitoring (e.g. crack surveys, movement pin surveys) is continued around the perimeter of the site to identify at the earliest opportunity any unexpected ground movements. Unexplained movements may be resolved through timely risk-based geotechnical investigations.

1. Introduction

1.1 Background

The department's Earth Resources Regulation unit is responsible for regulating mines in Victoria. As part of the approvals process, all mines are required to submit a work plan in accordance with the Mineral Resources (Sustainable Development) (Mineral Industries) Regulations 2019. All mines that extend over an area greater than five hectares or involve blasting and/or native vegetation clearance must have an approved work plan. Existing sites that propose to change a work plan for a mine are required to submit a work plan variation. The conditions for preparing and approving a work plan variation are essentially the same as for a work plan for a new mine.

The standard information to be covered in a work plan can be found in the Preparation of Work Plans and Work Plan Variations - Guideline for Mining Projects.

The department's Earth Resources Regulation unit requires that all mines are operated, rehabilitated and closed in such a way that they do not pose unacceptable risks to public safety, infrastructure, land, property and the environment. Therefore, a work plan submission must also address the identification of such risks and their control or mitigation. This guidance material has been prepared to assist mine owners in providing the required information in relation to risks arising from ground movements (geotechnical risks).

Mines that are exempt from requiring an approved work plan are required to adhere to the Code of Practice for Low Risk Mines or the Code of Practice for Small Quarries. These codes identify reasonably practicable practices for developing and operating low risk mines and they cover many of the same issues that are addressed in work plans for larger sites. However, if the final depth of an operation is proposed to be more than 5m then operators should apply the methodology explained in this guidance material. Operators are encouraged to read the current guidelines and, where appropriate, carry out a geotechnical risk assessment prior to commencement of excavation. The guidance material should assist low risk and small operators with avoiding unintended property or personal damages and unexpected costs.

This guidance material only applies to work plan submissions for open pit mines. It does not address geotechnical issues which may relate to underground mines’ or extractives’ work plan submissions.

1.2 Purpose

Geotechnical risks arise from movement of the ground during and following excavation. Risks may relate to slope failures, to changes to flows in water courses and surface water bodies or they may relate to movements of structures and infrastructure adjacent to or within the mine. The requirement is to carry out a prior assessment of the extent and magnitude of ground movements that could take place and to examine the potential impact of any ground movements on the area around and within the mine on the environment and infrastructure. The details of this assessment and its findings should be recorded.

If risks are identified where the risk level is not reasonably practical, then a record may also be required of the actions that will be taken to implement adequate controls. It is recommended that any documents pertaining to the risk assessment and the planned actions identified to control risks be submitted with the work plan.

Given this background, this guidance material has been prepared to assist mine owners in:

- understanding risk concepts;

- identifying geotechnical risks associated with mine developments;

- developing assessments of the scale of the perceived risks; and

- developing control measures to reduce risks to a level that is as low as practically possible.

2 Risk assessment

2.1 Risk concepts

To understand risk, it is useful to expand risk into its three parts: hazard, the likelihood of a hazard becoming an event, and the magnitude of the consequences of an event.

Hazard: a hazard is any physical activity, situation or condition with the potential to cause harm. Harm can involve human injury or death, damage to the environment, damage to physical assets or loss of production. An event occurs if harm occurs.

Likelihood: the likelihood of a hazard becoming an event (i.e. causing harm) indicates the chance that an event will occur, usually, within a given period of time.

Likelihood is a qualitative concept and is typically a subjective assessment of the chance of an event occurring. For some hazards it is possible to provide a more quantitative evaluation and a probability can be assigned on a scale of zero to one, where a probability of zero indicates that the hazard can never become an event and one indicates that it is guaranteed to become an event. Probabilities are usually determined on the basis of the frequency with which an event has arisen previously for similar conditions. In many situations frequency data is not available and if probabilities are assigned on the basis of limited historical data then they are also subjective. Depending on their sensitivity to the harm that may arise or their prior knowledge, different people will often assign different probabilities to an event for the same hazard.

Magnitude: the consequences of an event can vary in size from essentially harmless, when there is little need to remedy the harm caused, to severe where the losses from the event are large. The magnitude of an event can be measured in many ways, such as loss of life, loss of production, loss of habitat for wildlife etc.

Typically, a measure of the risk from an individual hazard is given by multiplying the probability of occurrence by the magnitude of the consequence. Consistent measures of probability and consequence need to be used if risks are to be compared.

Total risk is given by the set of all possible hazards and their individual risks. Establishing a single measure of risk for a number of hazards can be complicated and is not usually done.

In summary, the assessment of risk relates to future events and involves:

- an expectation of harm

- an element of uncertainty

- unwanted consequences

- an assessment of severity and likelihood of a loss.

Risks can be mitigated: hazards can be avoided or the likelihood of an event and/or the consequences of an event can be reduced. Risks can be managed, but only if the risks have been identified, quantified and understood.

This guidance material is seeking to increase the awareness of one particular area of risk in open pit mining and to encourage appropriate methods for identifying, quantifying and managing the risks.

For further information on risk concepts, refer to AS/NZS ISO 31000:2009 Risk management - Principles and Guidelines.

2.2 What is a geotechnical risk?

Geotechnical risk arises when a hazard can be identified that is related to ground movement. Unforeseen ground movements are likely to pose hazards but all movements should be considered as potentially creating a risk. Subsidence, landslips, toppling, settlement, heave, slumping and fracturing are all examples of ground movements that can lead to harm.

Other risks, closely related to geotechnical risk, can also arise. Disturbance of ground can lead to chemical leachates that are harmful to the environment or people. Prevention of heave or dewatering of an excavation may involve groundwater pumping that can reduce available water and increase harm from drought or deplete surface water bodies and harm the habitats supported by these water bodies.

Identification of geotechnical risks involves an understanding of the potential future movements of the ground, any related groundwater movements and the identification of the possible impacts of the movements on the environment, infrastructure, operations and people. Assessing the scale of the risks depends on an understanding of the possible consequences arising from the movements and their significance.

While it is suggested that an initial geotechnical risk assessment be completed, carrying out a geotechnical risk assessment should not be a static activity. As a site develops more knowledge may be available about the geological conditions and a greater understanding of the behaviour of the ground may develop. The areas being mined will alter and batters will continually be renewed. In all cases, risks may change. It is suggested that the assessment of geotechnical risk be an iterative and on-going process throughout the life of a site.

2.3 Geotechnical information required for a work plan or variation

Hazard identification, assessing risk severity, the implementation of risk controls and monitoring of outcomes for a safe and stable site may be considered when collecting the geotechnical information required for a work plan or variation. The suggested key requirements are to provide information on the following:

- The delineation of the potential area of ground movement around the mine.

- The existence of surface features that may be affected by or affect mine induced ground movements

- The geological and hydrogeological data for the affected area.

- The existence of subsurface features that may be affected by or affect mine induced ground movements.

- Information on the strength, compressibility, durability and quality of the ground to be mined or removed.

- Operational methods and the mine form (depth and batter slopes)

- Information on the wastes to be generated as part of the mining processes and the storage/disposal of the wastes.

- Dewatering requirements and methods including surface drainage and water disposal.

- Any analyses carried out to predict the stability of the site.

The following section provides information to support the suggested provision of the appropriate data within a work plan.

3 Carrying out a geotechnical risk assessment

3.1 Assessing the Geotechnical Risk Zone (GRZ)

The area affected by a mine is not limited to the perimeter of the excavation or to the limit of the mining licence within which the mine is located. Excavation related ground movements can take place over considerable distances away from the excavation perimeter.

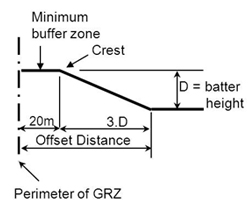

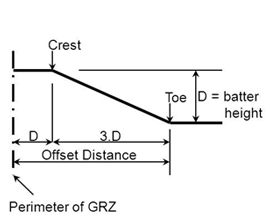

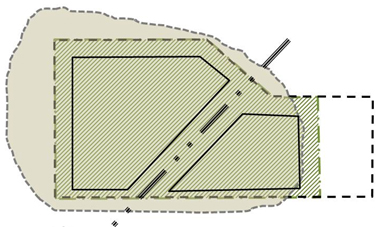

As a guideline, an offset distance of four times the final batter height may be used to define the limit of potentially significant ground movements from the foot of the final rehabilitation batters. The batter height is the height of the final crest measured from the closest foot of the batter and may vary around the mine perimeter. The offset distance is measured at right angles to the strike of the batter. This distance is based on an assumed final batter slope of 1:3 (vertical:horizontal) and a buffer strip equal to the height of the final batter. A minimum buffer strip of twenty metres (measured horizontally) may be required for operational reasons, so for batter heights less than twenty metres the offset distance may be three times the final batter height plus twenty metres. Figure 1 illustrates the suggested criteria for determining the offset distances.

Figure 1 Defining the GRZ

Note: Assumes a final batter slope of 1:3 (vertical:horizontal).

The area defined by the limit of potentially significant ground movements is hereafter referred to as the geotechnical risk zone (GRZ). The suggested GRZ should lie completely within the boundary of the mine lease if no further geotechnical assessment is to be undertaken.

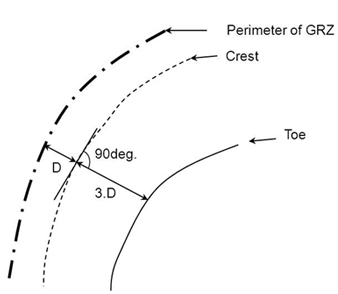

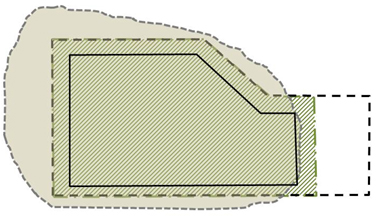

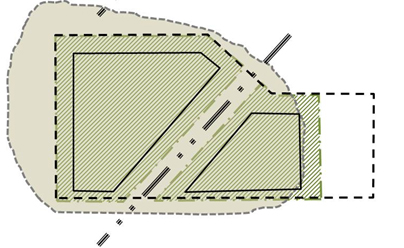

It should be noted that the GRZ is not determined from the proponent’s boundary in the first instance. The GRZ is based on the final area of the proposed pit floor, which defines the location of the designed or expected toe of the final batter around the site. The toe of the final batter is the determining line for the identification of the GRZ, although the designed or expected toe position is constrained by other factors. Thus, it is necessary to define the mine area and depth to satisfy the constraints of the proponent’s boundary, the offset distance for the GRZ perimeter from the designed or expected toe of the final batter and the extent of the mineral resource (depth and area) as well as any infrastructure that may be affected by ground movements. In practice, the suggested determination of the GRZ depends upon an iterative approach to satisfying all constraints (see Figure 2 for illustrations of GRZs for different scenarios.)

There can be occasions when it may be appropriate to reduce or extend the offset distance and the corresponding GRZ. Strong ground with few joints may show little movement within an offset distance much less than four times the batter height. Soft ground with shallow dipping strata and weak bedding plane surfaces may fail at distances well beyond four times the batter height. If the offset distance is to be altered from the guideline distance, then it is suggested that clear evidence be produced to justify the change.

Where the proponent wishes to reduce the GRZ, it must be demonstrated that a reduced GRZ will not have an impact on public safety, the environment or infrastructure. Normally this demonstration would require a geotechnical stability analysis with the appropriate controls in place to ensure the risk levels are at a level as low as reasonably practical.

Maintaining the offset distance at the guideline value when it is recognised that the offset distance should be larger to reflect the ground conditions may expose the operator to greater risks and should be avoided.

The GRZ may be altered by adjusting the final extent of excavation. Limiting the area of excavation may be one means of reducing the geotechnical risks (see section 3.3).

The GRZ potentially provides the basis for limiting the assessment of geotechnical risk geographically. The GRZ may be used for the assessment of public safety and/or infrastructure, land, property and environmental loss as required by the department's Earth Resources Regulation unit. Geotechnical risks relating to work place safety are subject to planning considerations under separate codes of practice and legislation. By suggesting that the GRZ falls within the mine lease, the potential risks to public safety and/or public and environmental loss should be relatively few.

The GRZ definition is based on ERR experience from coal material and unconsolidated sediments and may differ with different geology, such as basalt. Experiences within these materials should be demonstrated when determining the GRZ for hard rock materials.

Figure 2 Schematic Scenarios of a GRZ

3.2 Assessing the hazards and consequences

A register of all infrastructure, environmental areas or areas accessible by the public within the GRZ is suggested. Infrastructure includes public buildings, private dwellings, utility lines (water/gas pipes, water and wastewater drains, and power and communication cables) and roadways. Environmental areas include surface water bodies and ecologically significant vegetation. The register may also include all planned infrastructure or environmental plans for the area. The registered assets should be marked on the plan of the GRZ. For each registered asset an assessment may then be made of the possible hazards created by the presence of the asset in the GRZ in relation to any ground movements that might arise during the operation of the mine as well as during the period of rehabilitation and post closure. The potential consequences arising from an event associated with each hazard may then be identified.

As far as reasonably practicable, all necessary steps should be taken to ensure that all items of interest in the GRZ are identified, the hazards listed and the consequences arising from any event defined.

3.3 Examining the potential risks

Using the information developed for the register, it is recommended to assess the level of risk posed by the mine. For each hazard it is suggested to assess the potential impacts on public safety, the environment, land, property and infrastructure. For hazards where the assessed impacts are unlikely and the assessed consequences are low, there is no need for further examination. For all other cases the risks should be considered to be too high and it is necessary to mitigate the risks by completing a geotechnical stability analysis to assess controls to reduce risk to a level that is as low as reasonably practical.

Risk mitigation can take a number of forms. A basic approach is to reduce the extent or depth of the planned excavation in order to decrease the area of the GRZ so that the asset at risk falls outside of the boundary of the GRZ and the hazard is avoided. A more complicated approach is to relocate or remove the affected asset from the GRZ. If the asset lies within the area to be mined then removal at some stage is assumed. In this case, the suggestion is to time the removal to avoid any risk of failure of the asset due to the mining operations. In all other cases, geotechnical investigations are proposed to identify the necessary operations to reduce the risks to the infrastructure/environment to a level that is as low as reasonably practical.

In all cases, where a geotechnical risk is identified within the GRZ, it is advised to detail in the work plan or work plan variation the proposed measures to mitigate the risk.

3.4 Geotechnical investigations

In addition to those cases where a geotechnical risk is identified and may be mitigated by an engineering solution, including changes to the operation of the site, geotechnical investigations should be carried out when the:

- GRZ is defined using an offset distance from the toe of a batter that is less than the guideline value. This includes the case where operations will involve mining beyond the final batter toe line and the final batter form will be created by a buttress.

- method of working includes wet operations.

- method of working includes dewatering operations to maintain stability of the batters or floor of the mine.

Geotechnical investigations generally involve an assessment of the geological conditions at the site, determination of the geotechnical properties of all the geological materials and the determination of the stability of the batters and floor based on the proposed method of working. Geotechnical investigations and analysis of the results are recommended to be carried out by a competent person/organisation and use recognised methods for the evaluation of the stability of the site and the safety of any public assets.

Where a mining proposal requires geotechnical investigations to be carried out, the work plan/variation should identify geotechnical monitoring methods and procedures during the operation of the site for the purpose of assessing the adequacy of the plan.

Where geotechnical investigations are not required, it is encouraged to regularly monitor movement (e.g. crack surveys, movement pin surveys) around the perimeter of the site to identify at the earliest opportunity any unexpected ground movements. Unexplained movements should be resolved through timely risk-based geotechnical investigations.

Geotechnical investigations are not the only measure to demonstrate that risk levels are at a level as low as reasonably practical. Other controls which can be demonstrated to lower risk levels are horizontal bores, monitoring, etc. Simple monitoring techniques may involve measuring and monitoring the changes in crack width and direction of crack propagation to establish the extent of the unstable area. The simplest method for monitoring tension cracks is to spray paint or flag the ends so that new cracks or propagation along existing cracks can be easily identified on subsequent inspections. Measurements of tension cracks may also be as simple as driving two stakes on either side of the crack and using a survey tape to measure the separations. Other more sophisticated monitoring methods include inclinometers, piezometers, wireline and multipoint borehole extensometers.

4 Documenting the geotechnical risk assessment

4.1 Checklist for a geotechnical risk assessment

In the previous section the suggested main contributions for a geotechnical risk assessment are described. These are:

- Definition of the geographical area within which geotechnical risks should be examined. (Preparation of a map showing the extent of the GRZ).

- Identification of all current and planned assets (structures, infrastructure, natural features/environments) within the GRZ that may be affected by mining induced ground movements. (Preparation of a table of the assets and identification of the assets on the map of the GRZ).

- Determination of the hazards applicable to each asset associated with ground movements and the possible consequences. (Inclusion of the hazards in the table of assets).

- Identification of the likelihood and magnitude of the consequence of the hazards becoming events within the period of the mining operation and the subsequent period of site rehabilitation and post closure. Identification of the overall risk level for the hazard.

- For all hazards where the risk is deemed to be significant, a statement is required of the method(s) proposed for reducing the risk to a level that is as low as reasonably practical, either by reducing the likelihood or the magnitude of the consequences. Details of the information and data collected to support the adoption of each method should be provided.

- For all hazards posing significant risks for which a plan has been developed to reduce the risk to an appropriate level a statement is required detailing the method to be used to monitor and evaluate ground movements and their impact on the asset during operation and rehabilitation of the site. Monitoring and evaluation of the monitoring data are required to confirm that the risk is as predicted or to allow remedial work to be carried out if the risk appears to be higher than predicted.

For many small sites where ground controls or wet working are not required, it is likely that no public assets will be within the GRZ and therefore the reporting will be limited to the determination of the GRZ and the confirmation that the GRZ does not include reportable assets.

For sites where there are concerns and these cannot be removed by altering the extent or depth of the excavations, then it may be necessary to employ a qualified individual or organisation to carry out the geotechnical risk assessment and any geotechnical investigations required to demonstrate that the risks can be managed.

5 Conclusions

Identifying the risks to public safety, infrastructure and the environment is an important requirement for the preparation of a work plan or a work plan variation. A simplified method is advised for the identification of the assets and the hazards associated with ground movements induced by the mine.

The method is proposed to explore the potential risks from mining and where necessary to consider revision of the mining operations to reduce the risks. Where the assessed risks are deemed to be high then it is recommended to reduce the risks to a level that is as low as reasonably practical and to demonstrate the proposed methods for achieving the required risk reduction.

In all cases where engineering, operational or management approaches to risk reduction are required, the preparation of the required investigations and plans is advised to be carried out by an individual or organisation competent to carry out such work. The information requested for inclusion with the work plan should be sufficient for ERR to review the assessment of the geotechnical risks and any actions arising from the assessment.

References

- Mineral Resources (Sustainable Development) Act 1990 (MRSDA)

- Mineral Resources (Sustainable Development) (Mineral Industries) Regulations 2019

- National Mines Safety Framework – Draft Code of Practice for Underground Mines

- National Mines Safety Framework – Draft Code of Practice for Open Pit Mines

- Code of Practice for Low Risk Mines

- AS/NZS ISO 31000:2009 Risk management - Principles and guidelines

- Geotechnical guideline for extractive industry (PDF 400.4 KB)

- Work plan guidelines for mining licences

Page last updated: 02 Jun 2021